I have previously talked about Concrete Cracking …….but how do you stop random cracking across your driveway concrete?

Well the best way is to control cracking by making sure it cracks where you want it to and the cracks are neat.

To do this you need ‘joints’ which ensure the cracks in the right place.

A good rule of thumb for a reinforced concrete slab is the joint spacing should be no more than 25 x the depth. That is for a 100mm thick slab the joints should be every 2.5m.

Un-reinforced and I wouldn’t be happy with a joint spacing of more than 15 x the depth.

Contraction Joints

Contraction joints, sometimes called control joints, are the most common type of joints. They are formed to ‘break up’ slabs poured over large areas into the smaller final slabs.

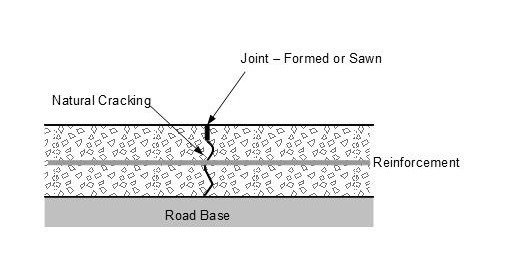

The following sketch shows some of the characteristics of a contraction joint.

The key features are:

- A joint is either formed, or sawn, to weaken the concrete at the joint position. Below is a picture of a joint forming tool

- Below the formed joint the concrete naturally cracks with a rough surface. This rough surface stops one slab moving up or down relative to the other slab.

- Reinforcement continues across the joint to hold the joint closed. This reinforcement should be be weaker than the main slab mesh. One way to achieve this is by cutting out alternate bars in the reinforcement mesh.

Problems

Here are some of the the things that go wrong and mean you get random cracking spoiling the look of your concrete paving.

- Too Much Steel

This can be;- The mesh has not been weakened across the joint by removing alternate bars.

- Two sheets of reinforcement mesh have been overlapped across the joint.

- Shallow Initial Formed Joint This joint should be 1/3rd the total depth of the slab other wise it may not weaken the slab enough to form the crack at the intended position. When I have used a formed joint I usually run an angle grinder along the bottom of the groove the morning after the pour to make sure it is deep enough.

- Joint Not Sawn At Right Time If the joint is to be a saw cut it should be done 16 -24 hours after the pour. Too soon and the saw will pull stones out of the concrete leaving a rough edge. Too late and the concrete will have cracked at a place other than the intended joint.

You may think your concreter will know all this. It’s a sad fact that a lot either don’t know, or don’t care, judging from the jobs I see!

For more posts on on getting your paths and driveways correct see Concreting