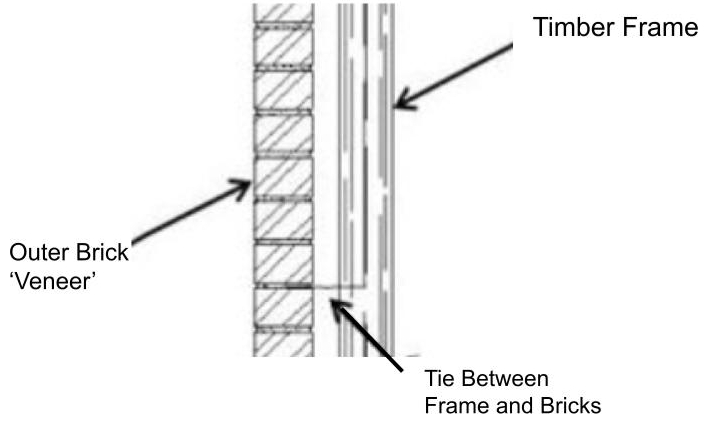

When considering insulation a typical Australian brick veneer wall would be:

| Element |

R value |

| Outside surface air layer |

0.03 |

| 110mm brick |

0.08 |

| 25mm cavity |

0.12 |

| R1.5 Insulation |

1.5 |

| Plasterboard 10mm |

0.06 |

| Inside surface air layer |

0.12 |

| Total R value |

1.91 |

| U value = 1/R |

0.51 |

The heat losses or gains for 150 sq m (fairly typical external wall area) of this type of brick veneer wall at 15 degrees above, or below, outside temperature will be:

Area x ‘U’ x temperature difference = watts per hour

150 m2 x 0.51 x 15 degrees = 1178 watts per hour

Heating/Cooling Requirement = 1.17kw/hour

To change the U value calculation simply change the value of the element or add an element in.

Example 1 Changing the Insulation to R 2.0

New Total R = 2.41

New U = 0.41

Reduced Heating/Cooling requirement to 0.92kw/hr

Example 2 Adding a reflective building wrap to example 1 (increases cavity R by 0.18

New Total R = 2.59

New U = 0.39

Reduced Heating/Cooling Requirement to 0.87kw/hr

Remember this isn’t the total heating requirement as heat is also lost through windows, ceilings floors and ventilation.